Custom Phenolic CNC Machined Parts

Custom CNC Machined Phenolic Parts

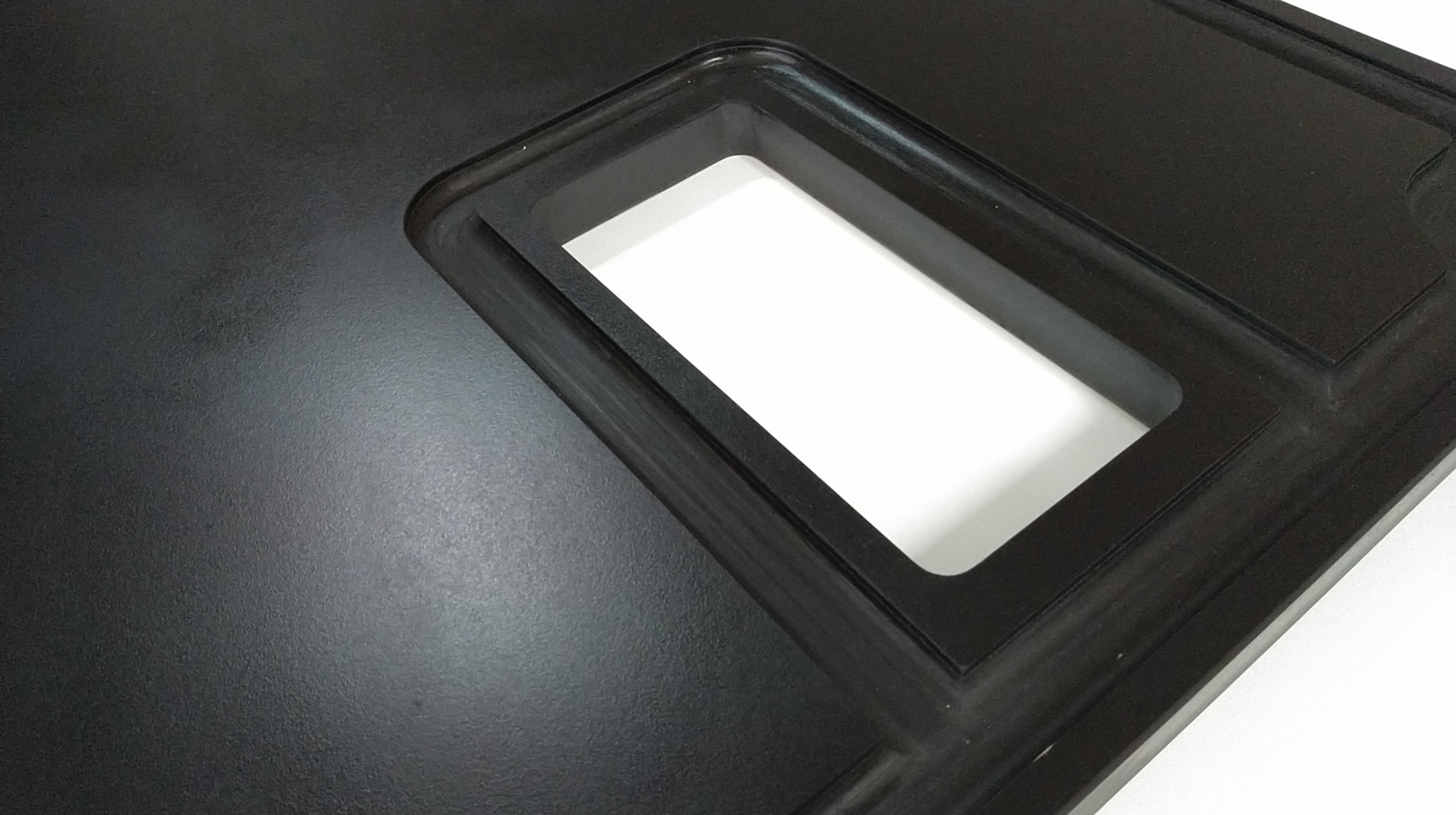

We specialize in CNC machining of laboratory-grade Fundermax phenolic resin panels, engineered for strength, durability, and dimensional stability. These composite panels are created by curing resin-impregnated kraft layers under high heat and pressure, producing dense, flat sheets with excellent screw-holding strength, dielectric properties, flame resistance, and low moisture absorption.

Panels remain flat under heavy loads and can withstand hundreds of pounds of pressure from weighted materials.

Capabilities

- Precision cutouts, grooves/notches, beveled or radiused edges

- Ferrule inserts and countersinks for recessed fasteners

- Close-tolerance machining on 3-, 4-, and 5-axis mills, lathes, and routers

Industry Applications

- Semiconductor & Electronics: Circuit board holders, terminal boards, and other electrical components (high dielectric strength).

- Defense: Components meeting stringent Mil-Spec requirements for aerospace and marine environments.

- Medical: Devices and diagnostic equipment (chemical resistance and low moisture absorption).

- Aerospace: Parts requiring high impact strength and dimensional stability.

Advantages

- Close tolerances, excellent machinability, non-warping flatness

- Very low coefficient of thermal expansion; very low moisture absorption

- Flame retardant with strong dielectric performance

- Often lower cost than alternative engineered materials

Best Used In:

- Robotics & automation workstations

- Laser & microscope tables

- Pneumatics, cleanroom, and ESD environments

- Computer monitoring stations & classroom applications

Availability

Custom parts are made-to-order with no minimum quantity. Standard panel thicknesses: 1/4",1/2", 3/4", 1" (6, 13, 19, 25 mm).