Fundermax Solid Phenolic Panels Sheet Color Through Core

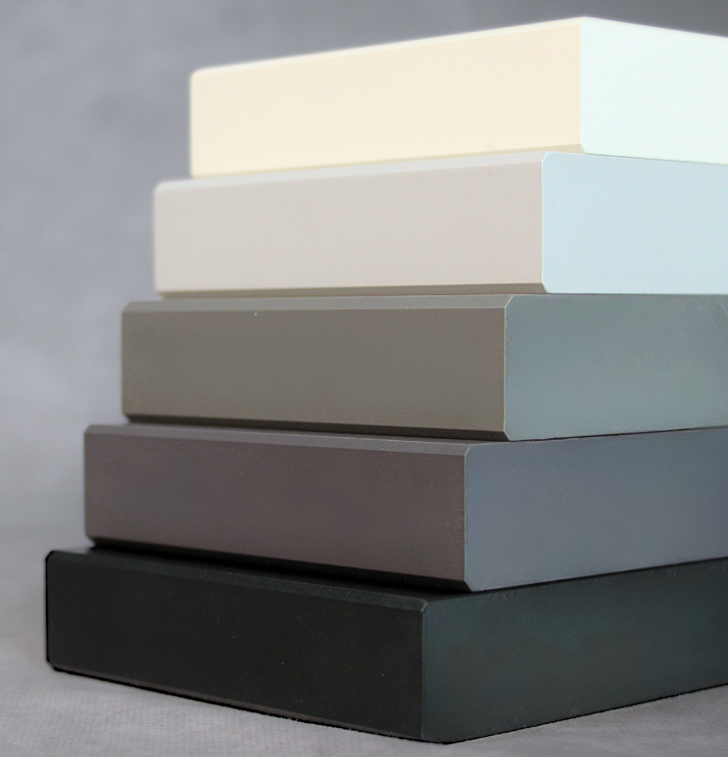

Color Through Core |Available Color Options

IN STOCK

Available In Stock Sizes

FABRICATED OR FULL SHEETS:

| Sheet Sizes | SQ/FT Per Sheet | Thickness (in) | Metric (mm) | Lbs/ft2 |

|---|---|---|---|---|

| 64.18" x 144.5" | 64.39 | 1" | 25mm | 7.24 |

| 73" x 110.25" | 55.89 | 1" | 25mm | 7.24 |

| 64.18" x 144.5" | 64.39 | 0.75" | 19mm | 5.4 |

| 73" x 110.25" | 55.89 | 0.75" | 19mm | 5.4 |

| 64.18" x 144.5" | 64.39 | 0.50" | 13mm | 3.62 |

| 64.18" x 144.5" | 55.89 | 0.25" | 6mm | 1.81 |

Recent Photos

Color Through Core |Overview

As a qualified dealer, fabricator and stockist of Fundermax™ industry standard laboratory grade solid phenolic panels, we are pleased to introduce to the North American market, the new and innovative Color Through Core, solid phenolic lab panels.

In addition to the industry standard and traditional black surface and core MaxRE material, Fundermax™ is introducing a new color range that includes white core; pastel grey core, charcoal grey core, and volcano grey core.

Details and Specs

The newly introduced and improved material for applications for sterile and chemically resistant laboratory work surface environments, offers the following intrinsic features and benefits:

- Lower cost than Epoxy or alternative SPC phenolics

- Chemical resistance to the most extreme chemicals

- Durability / impact resistant

- Heat resistance / Thermal shock resistance

- Scratch & abrasion resistance

- Double sided color and Color Through Core

- Uniform color from surface to the core

- NO Black Edge

- No edge dressing or banding required

- Light weight at 7 Lbs per sq ft 1" thick

- Reduced shipping weight & freight costs

- *Superior depths and lengths for Field fabrication up to 64" x 144" (1630 x 3660mm)

- Excellent machinability in shop or field

- Easier fabrication of sink holes for epoxy, polyethylene or stainless steel sink Bowls

- Anti-Static

- Anti-Bacterial

- Fire rated Class "A"

- Food Safe (NSF/ANSI) -51 Compliant

- MR 2.1 & 2.2 - Construction Waste Management

- MR 3.1 & 3.2 - Material Re-use

- MR 5 - Regional Materials

- MR 6 - Use of rapidly renewable materials

- IEQ 4.4 & 4.5 - Low emitting materials

Certified to Quality Management Systems:

- ISO 9001:2015

- ISO 50001:2018

- ISO 14001:2015

- ISO 45001:2018

- 10 year product warranty

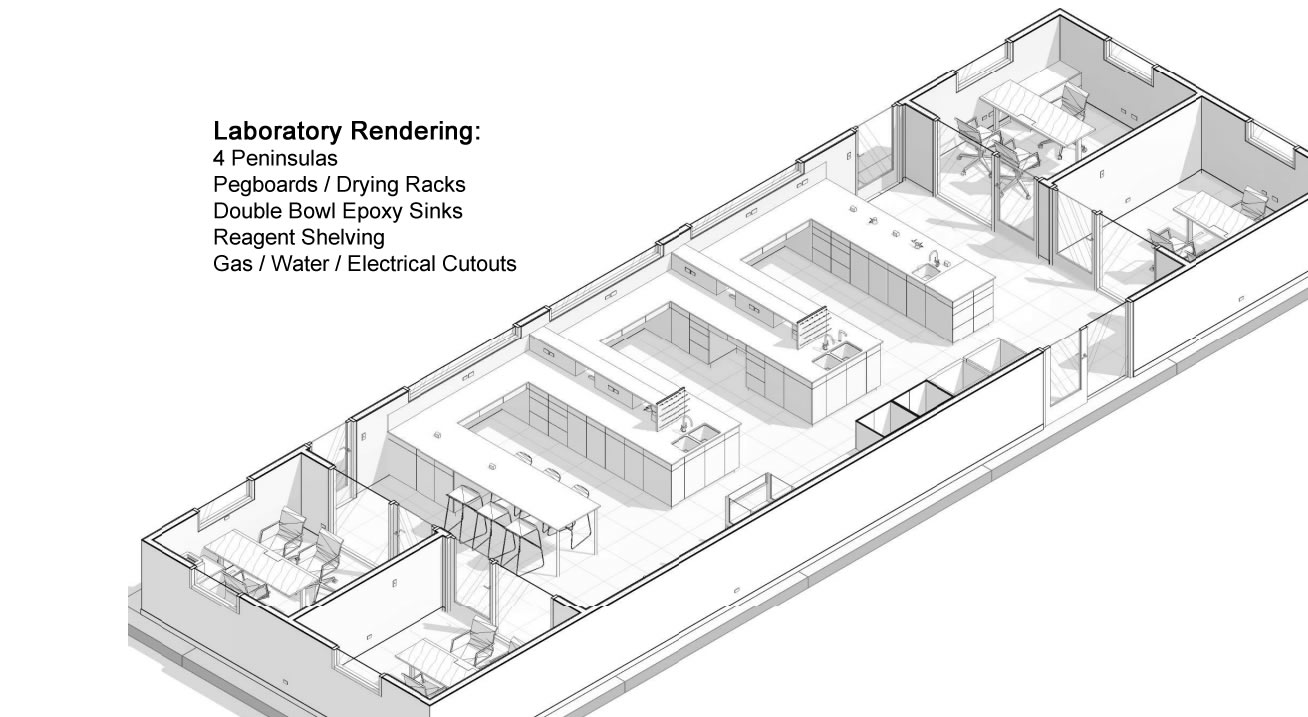

Applications

Max Resistance2 affords the end users in Water Treatment plants, K-12 thru University - Chemistry / Biology / Physics & Flex labs, Pharma, Medical & Dental Facilities, R&D, a 25% higher impact and scratch resistance than traditional SPC or alternative phenolic resin countertops, and 3X higher abrasion resistance when compared to EBC, Epoxy or Melamine surfaces. Phenolic material and in particular, Max Resistance2, with its unique RE surface technology (top and bottom) affords an integrated double hardened, double cured poly acrylic surface giving rise to greater resistance for chemicals, hygienic and of course moisture. The homogenous material thus becomes the perfect choice for wet areas around sinks of laboratories. Moreover, since these materials also afford superior antibacterial properties, chemical, heat and scratch resistance, it is no wonder they are rapidly becoming the surface of choice for lab designers.

Architects & lab planners have been requesting alternatives to white and grey core Epoxy resin and other black core / edge phenolic materials and now they are available and in stock. Design your labs accordingly with emphasis on chemical and physical attributes with style and color, from the colored surface to the interior Core of the Phenolic material. Contact us for further information, samples and pricing.